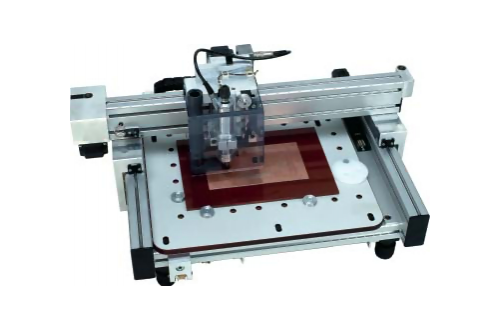

The Bungard CCD/2 is a high quality Computer Controlled Drilling machine with semi-automatic tool change.

- In contrast to the CCD/MTC the CCD/2 has a half sized work area (325 x 250 compared to 325 x 495mm) and an integrated control unit underneath the table.

- Compared to the ATC models, the software interrupts the operation during the tool change and the new tool is changed manually (turning the knob changes by a quarter turn; motors remain empowered and hold the position).

- The CCD/2 has the same robustness and precision as all the other CCD models.

- It is ideal as an entry-level model for isolation milling.

- If you want to operate the CCD/2 with cooling, you need to protect the control unit from the cooling.

- Please contact us beforehand.

- In contrast to all other CCD models, the machine zero point is at the front left.

- The X axis is the traverse over the table, whereas the Y-axis is located on table level.

- The CCD/2 can not be converted to automatic tool change.

- If you possibly want to upgrade at a later time, please contact us before purchase.

- If necessary we can create a special version.

Technical Data:

- Power supply: 110-240 V, 50-60 Hz + vacuum cleaner (1500W)

- Range of RPM: 30.000 - 63.000

- Traveling speed: 1 - 9000 mm/min

- Software resolution: 0,0001mm (0,1µm)

- Mechanical resolution: step resolution: Software selectable: 1 mil, ½ mil, ¼ mil (= 6.35 Mikrometer)

- Tool diameter: 0.1mm - 3,175mm (recommended, bigger tool diameter possible)

- Position accuracy: 20 ppm (0.002%) over the entire work space:

- Maximum position speed per axis: 9000/mm/min (=150 mm/s)

- Maximum working speed per axis: 9000/mm/min (=150 mm/s), individual setting on a per-tool basis, independent from position speed

- Drill speed: 5/s (= 18.000 holes/h= 300 holes/min)

- Required Accessories: Computer

- Board fixation: span fixing, clamp fixing, reference pin system, stack processing possible

- Option: vacuum fixation

- Weight kg : 30

- Dimension mm: 700x550x300

- Work area mm: 270x325x38

- Tool change: no