| ESD_safe |  |

|---|---|

| Brand : | WELLER |

| EAN code : | 4003019447190 |

| Code number : | 810 00033 |

| Supplier : | WATC100M |

| Model : | WATC100M |

| Minimum temperature (°C) : | -10 |

| Maximum temperature (°C) : | 45 |

| Power (W) : | 50 |

| Weight (g) : | 1754 |

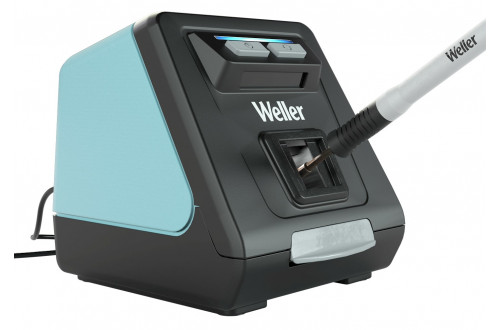

WATC100 cleans soldering tips and tweezers in a second without spilling any debris on your workbench.

With the WATC100 the life of your soldering tip will be enhanced, and soldering results will be of higher quality and consistency because of better heat transfer from the tip to the components.

Save time, money and protect your investment.

The first High performance cleaning process, cleans tips fast and clean in only 1 second with automatic on/off function.

Debris free workspace, no splashes that could damage workpiece, for total control of the soldering process.

Universal cleaning of soldering tips and desoldering tweezers, giving highest flexibility in demanding soldering environments.

Improved heat transfer delivers consistently high quality soldering results.

Optimal tip care extends tip life up to 2 times compared to manual cleaning.

ESD safe unit, that can be used in all production facilities.

The compact footprint allows optimal usage of the workbench.

2 differents brush types available for different levels of cleaning.

For large, heavy duty soldering tips.

Reusable due to robust design.

WATC100 cleans soldering tips and tweezers in a second without spilling any debris on your workbench.

With the WATC100 the life of your soldering tip will be enhanced, and soldering results will be of higher quality and consistency because of better heat transfer from the tip to the components.

Save time, money and protect your investment.

The first High performance cleaning process, cleans tips fast and clean in only 1 second with automatic on/off function.

Debris free workspace, no splashes that could damage workpiece, for total control of the soldering process.

Universal cleaning of soldering tips and desoldering tweezers, giving highest flexibility in demanding soldering environments.

Improved heat transfer delivers consistently high quality soldering results.

Optimal tip care extends tip life up to 2 times compared to manual cleaning.

ESD safe unit, that can be used in all production facilities.

The compact footprint allows optimal usage of the workbench.

2 differents brush types available for different levels of cleaning.

For large, heavy duty soldering tips.

Reusable due to robust design.

| Code number | Supplier | Description | ||

|---|---|---|---|---|

| 1x | 810 00036 | WATCBM | REPLACEMENT METAL BRUSHES FOR WATC100 |

| 1x | 810 00034 | WATC100T | REPLACEMENT TRAY FOR WATC100 |

| 1x | 810 87718 09 | T0058771809 | POWER SUPPLY FOR WATC 24VDC SPARE |